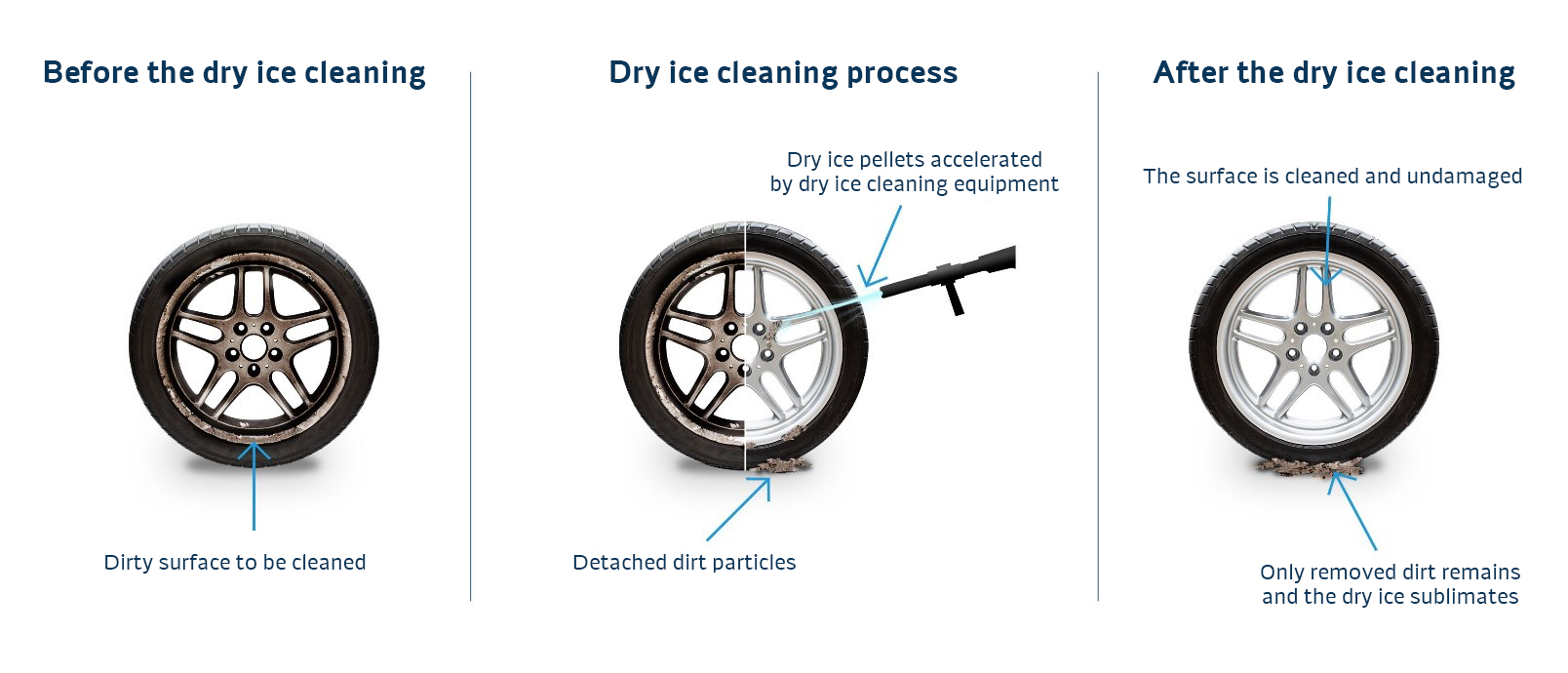

The dry ice cleaning process uses dry ice as the blasting medium. Dry ice is solid carbon dioxide (CO2) and -78.4 °C cold. This extreme cold of the dry ice pellets shock freezes the dirt in seconds, creating mirco-cracks in the contamination. The pellets are tremendously accelerated by dry ice cleaning equipment in conjunction with compressed air and penetrate the contamination through the cracks. Due to the pressure of the accelerated blasting medium and the resulting cold shock, the dirt particles detach from the surface to be cleaned. Finally, only the removed dirt remains, as the dry ice sublimates completely into CO2-shaped gas into the environment.

Abrasive processes with hard abrasives, such as sandblasting, roughen the surface to remove dirt and thus damage it. The dry ice blasting process is a particularly gentle process for sensitive objects and can increase their service life. In addition, the blasting process can be adapted to the properties of the workpiece to be cleaned by adjusting the pressure, the amount of ice and the ice grain size.

Dry ice cleaning is one of the most environmentally friendly cleaning methods, as no chemicals are used and no harmful vapors are produced. In addition, there are no residues of the abrasive that need to be disposed of. Furthermore, it is suitable for industries in which blasting media such as sand or water cannot be used or are even prohibited by law. Due to the temperature of the dry ice, this cleaning method is antibacterial and suitable for the care sector and food industry.

In addition, the abrasive used is odorless, non-flammable or conductive.

Another advantage of dry ice blasting is its low cost, which can be achieved as follows:

The dry ice cleaning process is versatile. Whether in mechanical engineering, printing plants, municipalities or the automotive and pharmaceutical industries. You achieve the best possible cleaning result with little effort.

Clean cars or motorcycles with dry ice. Thanks to dry ice, you can perform an engine wash, which was prohibited by many manufacturers with high-pressure cleaners or water. Also dirty rims, windows and door edges can be made to shine again.

Dry ice is equally suitable for interior cleaning. Easily remove stubborn stains, dust and dog hair from car seats, floor mats and the entire interior. In addition, you can neutralize unpleasant odors, such as smokers' vehicles or the smell of vomit.

Cleaning by means of dry ice is frequently used in casting processes such as injection molding. This cleaning process is particularly popular because it increases the service life of the molds and can remove even the most stubborn deposits from molds. Residues of paint, varnish, rubber or silicone can be easily removed from injection molds (plastic parts production) or aluminum die casting molds thanks to the blasting process. In addition, dry ice cleaning of injection molding as well as die casting machines can reduce wear, cleaning effort and machine downtime.

Conveniently remove graffiti, climbing plants, stickers or other environmental contamination. Dry ice blasting also removes soot, which is why this cleaning method can be used in The dry ice cleaning is a popular method to clean facades. Fire restoration can be used. Even half-timbered houses can be cleaned easily and gently with this cleaning method without destroying the wood grain.

Cleaning with dry ice works on metal, wood, stone and plastic such as:

Fences, stairs, gates, bricks

Sidewalk, tiles, parquet

Dry ice cleaning is not a miracle cure, however, and this cleaning method reaches its limits in the case of silicone-containing paints or rust.

Do you want to know if dry ice cleaning is suitable for your problem or are you unsure which device to use, then feel free to contact us and we will help you.

It is important that sensitive electronic parts are cleaned particularly carefully and gently. Switch cabinets, circuit boards, control elements and other electronics can be easily cleaned with dry ice.

Dry ice cleaning removes grease, oil, soot and lime as well as other contaminants in no time without leaving moisture and damaging components.

More examples in our "Cleaning with dry ice" videos

We produce our dry ice cleaners in Germany, which allows us to guarantee high quality and adapt the devices to your individual requirements. Feel free to test our products directly on site in Tamm, Baden-Württemberg, or visit us at our stand at the trade fair..

We offer innovative, lightweight and compact dry ice blasting equipment at fair prices. The Südstrahl GmbH & Co. KG dry ice cleaning machines are suitable for continuous operation as well as economical in dry ice and compressed air consumption.

We are available for you at any time and will be happy to answer your questions about cleaning with dry ice. We will be happy to advise you personally on +49 7141.13381-10 or contact us conveniently via our contact form..